On the fence about 3D printing services? Yes, they’re relatively new, but the first 3D printer was created by Charles W. Hull in the mid-’80s.

So has the technology advanced enough to make the jump to 3D printing?

Let’s take a closer look. In the sections below, you’ll find out how far 3D printing and manufacturing have come. Once you learn the benefits of modern printing, you can finally decide if it’s right for you.

1. Printing Services for Prototypes

Once you choose a 3D printing service, you simply send your design specs over and wait for them to return the prototype.

Manufacturers create prototypes in one of three ways:

- Cut material away from a solid block, like metal

- Injecting heated material into a mold, used for large volumes

- Printing a product, layer by layer

The drawback of the first item in the list above is the waste. The manufacturer starts with a large block of material and shears away the unwanted parts, leading to waste.

The second option in the list above requires the creation of molds. They cost extra resources to create but are worthwhile if you produce large volumes.

The last on the list avoids waste and doesn’t require molds or large batches.

2. Lightning-Fast Turnaround

If you plan to scale your business or your new design, you need the convenience to design, manufacture and test your parts at speed. Otherwise, you’re wasting valuable time and money. Plus, you can modify it on the fly.

Yes, your design can be modified and reprinted on the fly, cutting your downtime to zero after you find the right 3D printing service.

With the right 3D printing service, you can upload your new specs from the comfort of your own office and email them to one of your local 3D printing services. The new prototype could be in your lap before the end of the business day.

3. Cost-Effectiveness

When you cut material away during the manufacturing process, that material is wasted, therefore so is the money you used to purchase that material. So unless you plan to make large volumes of prototypes, creating molds is a waste of money.

3D printing avoids both obstacles. They’re also less labor-intensive and require fewer engineers to operate the machine.

4. High Versatility

Traditional manufacturing requires a wide variety of tools, dies, and molds. Each project, and each part, is different, which translates to different tools, dies, and molds for each project. This requires extra time and labor, hiking the price tag.

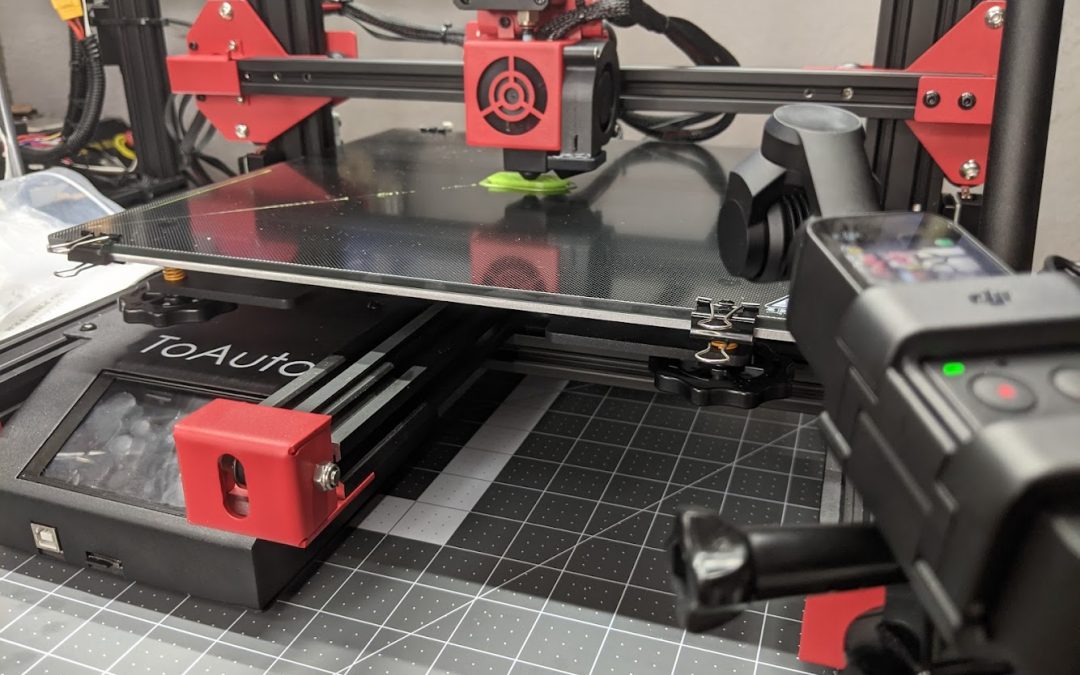

3D printing is different. Engineers feed your design specs into a software slicer which tells the printer what to do. Little to no change in the physical machinery is required.

The machinery also gives the power to create geometries otherwise impossible with traditional machinery.

What’s Next?

Now that you better understand the benefits of 3D printing services, what’s right for you? Do you need your parts created from a solid block of material? Do you need large volumes, or are you looking for cost-effectiveness and speed?

If you’re interested in rapid 3D prototyping, research, development, or manufacturing, reach out to a 3D Printing Expert today.