In the ever-evolving landscape of manufacturing processes, 3D printing has emerged as a disruptive force, captivating the imagination of businesses and consumers alike. At 3D Musketeers, we frequently encounter the question: Is 3D printing over-hyped? Let’s dive into the nuances of this technology and uncover its true potential.

Decoding the Hype: Understanding 3D Printing Technologies

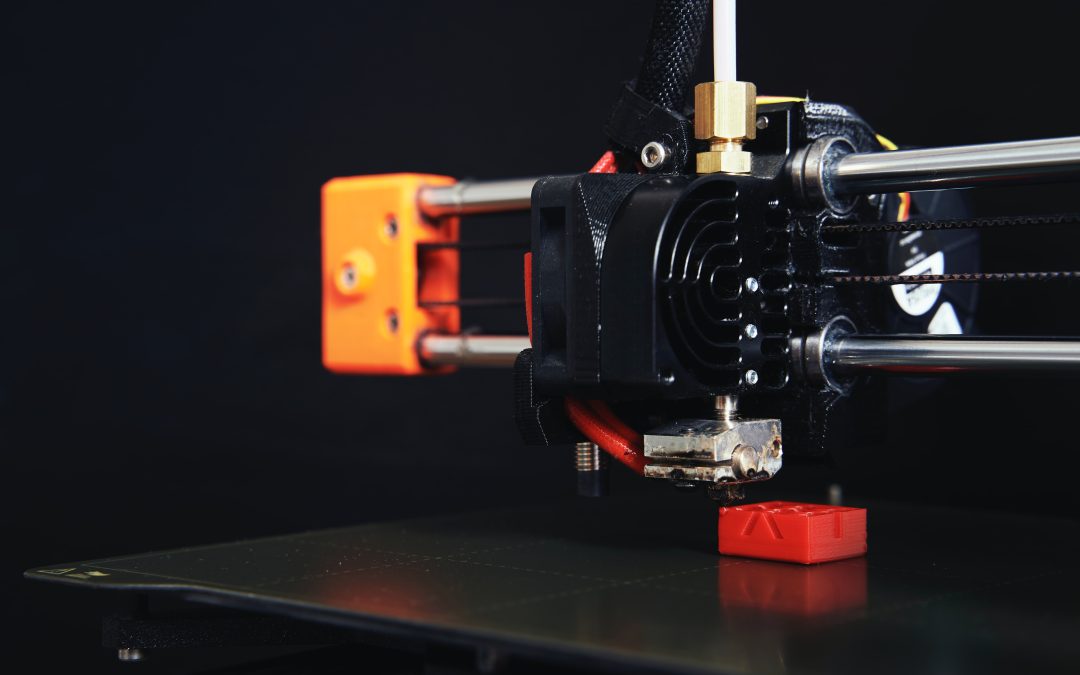

The realm of 3D printing encompasses a range of additive manufacturing technologies that allow the creation of physical objects from 3D models. It offers critical advantages over traditional manufacturing, such as faster prototyping, cost advantages, and design flexibility. However, it is crucial to recognize that 3D printing is not a one-size-fits-all solution.

Unveiling the Limitations

While the 3D printer market continues to expand, it’s essential to acknowledge the limitations of 3D printing. Surface finish and material properties may not match traditional manufacturing processes like injection molding. Furthermore, certain materials required for specific industrial applications may be limited in the 3D printing materials market.

At 3D Musketeers, we believe in utilizing 3D printing where it excels—such as rapid prototyping and low-run manufacturing—and collaborating with traditional manufacturers when necessary to harness the strengths of both approaches.

Embracing the Evolution: Applications and Trends

As the 3D printing industry grows, we witness exciting advancements and applications. 3D printing has found its place in diverse fields, from construction to healthcare. Let’s explore some of the notable aspects of 3D printing:

1. Industrial Applications: 3D printing is increasingly used in industrial settings, where industrial printers and specialized materials enable the production of complex and customized components.

2. Consumer Market: 3D printing is gaining traction, empowering average consumers to turn their ideas into tangible objects. Online services and user-friendly 3D design programs have made it more accessible.

3. Materials and Techniques: The availability of diverse materials, ranging from plastics to metals and even biocompatible substances, broadens the possibilities of 3D printing. Techniques like selective laser sintering (SLS) and fused deposition modeling (FDM) contribute to expanding the scope of applications.

Looking Ahead: The Future of 3D Printing

The potential of 3D printing is undeniable, and while it has already made substantial strides, its journey is far from over. We envision a future where 3D printing becomes integral to various industries, complementing traditional manufacturing methods and revolutionizing production processes.

At 3D Musketeers, we remain committed to staying at the forefront of this transformative technology. Our expert team of 3D printing specialists and designers collaborate with clients to bring their visions to life. Whether you are a beginner or an expert in 3D printing, our services cater to your needs.

Join the 3D Musketeers Community

To stay updated with the latest trends, advancements, and projects in the 3D printing industry, follow us on Facebook and Twitter. Our YouTube channel also has insightful content, so subscribe to 3DMusketeers.

If you have any questions, collaborations, or ideas about 3D printing, please contact us through our contact page. We’re here to guide you through the exciting world of 3D printing and help you unlock its true potential.

3D printing is not over-hyped; it’s an innovative force reshaping industries and driving us toward a future of limitless possibilities. Let’s embark on this journey together, embracing the power of 3D printing and revolutionizing how we create and manufacture.

Recent Comments