Traditional manufacturing methods, including casting, forging, and subtractive manufacturing, have been industry stalwarts for centuries. These techniques have shaped everything from the automotive to the building industry, delivering durable products with excellent mechanical properties such as tensile strength. We’ll try to dive deeper into the differences between 3D printing vs. conventional manufacturing.

3D Printing: The Digital Revolution

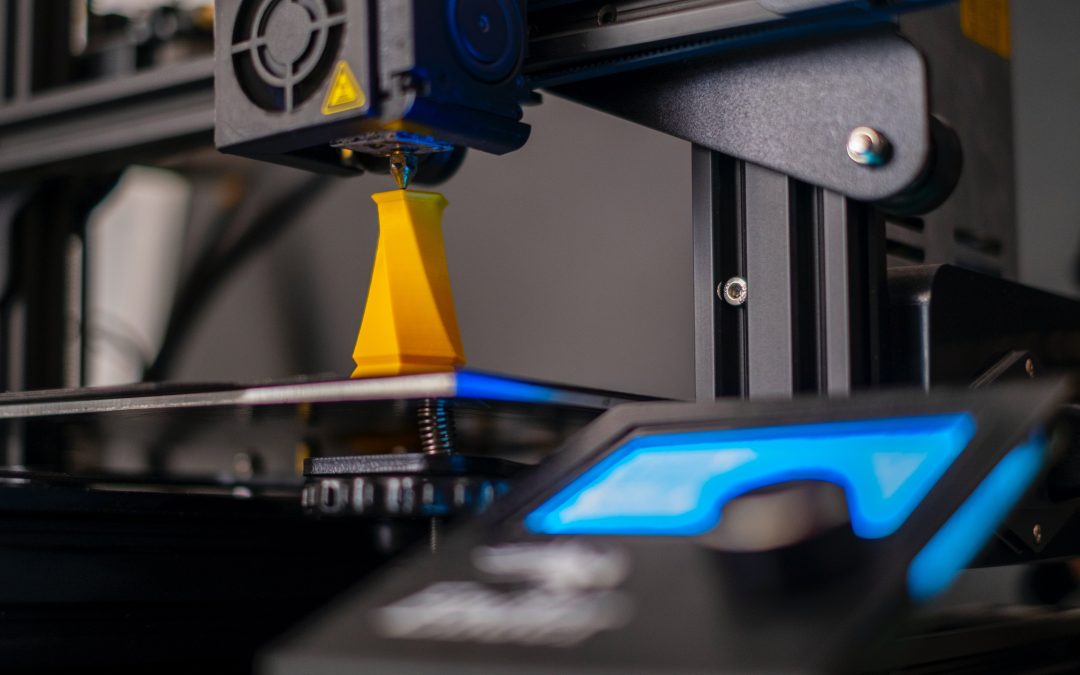

The rise of additive manufacturing technology has challenged the old guard, promising design freedom and cost benefits that traditional manufacturing can’t match. Using computer-aided design (CAD) to create detailed 3D models, a 3D printer builds objects layer by layer from raw material. The impact of 3D printing on manufacturing processes is unprecedented.

The Clash of Manufacturing Titans

Design Freedom and Rapid Prototyping

Thanks to its layer-by-layer approach, additive manufacturing technology excels at creating complex designs and rapid prototyping. Physical prototyping, a process often fraught with labor costs and time constraints, becomes far more efficient and cost-effective.

Cost Structure and Material Selection

3D printing lowers labor costs and increases flexibility in material selection, but equipment and material costs can be high for specific projects, especially for a metal 3D printer or high-performance printing. The cost-benefit of traditional manufacturing when producing large quantities using predefined material deposition patterns is worth noting.

Construction-Scale Additive Manufacturing Techniques

3D printing construction is a prime example of the technology’s potential. Companies have revolutionized the construction industry, using concrete printing to build entire apartment buildings. Unlike conventional concrete, concrete materials offered new properties and significant cost savings compared to traditional construction costs.

Advantages and Limitations of 3D Printing

The benefits of 3D printing include design flexibility, reduced labor costs, rapid prototyping, and the ability to produce complex designs. However, the limitations of 3D printing involve higher prices for some advanced materials and the necessary technical expertise.

However, like all technologies, 3D printing has its limitations. Skilled labor is required to operate and maintain printers, particularly metal 3D printers and other advanced models.

Curious about the process of 3D printing or how 3D printing construction might benefit your project? Ready to explore the unique capabilities of additive manufacturing technology? Let’s get in touch.

Seizing the Future with 3D Musketeers

At 3D Musketeers, we’re pushing the boundaries of manufacturing technologies, driving forward the capabilities of 3D printing processes. Whether it’s crafting a custom piece on a metal 3D printer or creating the architectural design for a new building, we’re committed to making your vision a reality.

Are you ready to embark on your manufacturing journey? Reach out to us today.

Stay on top of the latest in 3D printing and digital technologies by following us on Facebook and Twitter. Also, remember to subscribe to our YouTube channel. Together, let’s explore the exciting world of additive manufacturing.

Recent Comments