3D Printing: From Digital Files to 3D Objects

How does 3D printing work? The journey from an idea to a three-dimensional object starts with a digital design. Using Computer-Aided Design (CAD) software or 3D scanners, we can create or capture a 3D model. This digital file holds the blueprint for what our 3D printers will bring to life.

The 3D Printing Process: Layer by Layer

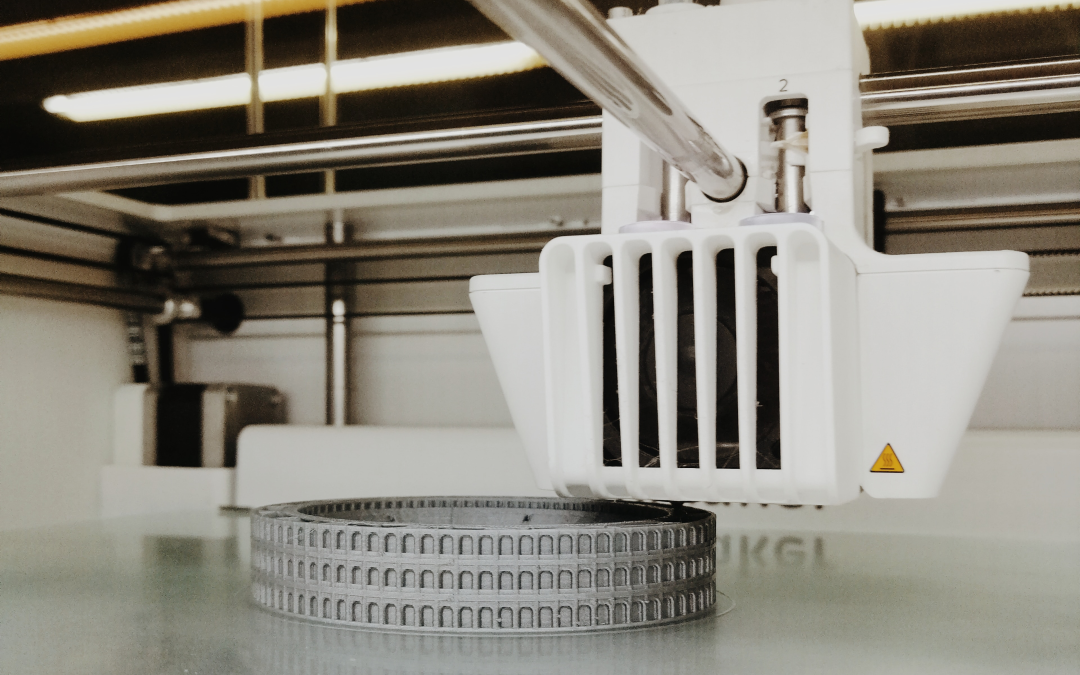

3D printing, also known as additive manufacturing, contrasts starkly with traditional manufacturing methods. Instead of a subtractive process where the material is removed, 3D printing builds objects from the ground up. It uses an additive process where successive layers of material are laid down to create a solid object.

Variety of 3D Printing Techniques

There are several types of 3D printing, each with unique processes and applications. Standard methods include Fused Deposition Modeling (FDM), where a heated nozzle extrudes plastic filament, basically like a computer-controlled hot glue gun, and Selective Laser Sintering (SLS), where a high-power laser fuses small particles of plastic, metal, ceramic, or glass powders into a mass that has the desired three-dimensional shape.

For instance, Direct Metal Laser Sintering (DMLS) and Multi Jet Fusion (MJF) employ a powder bed fusion method to print with various materials, including metal powders. In contrast, Digital Light Processing (DLP) and Stereolithography (SLA) use a light source, often UV light, to harden liquid material.

A World of Applications for 3D Printing

3D systems and 3D printing services have found a home in various industries. Applications of 3D printing span from creating 3D printer filament for hobbyists to producing intricate fuel nozzles for aerospace applications.

From the automotive to the medical industries, additive manufacturing processes are transforming traditional manufacturing, reducing costs and enabling designs and structures that weren’t possible with conventional manufacturing processes.

The Final Stage: Post-Processing

Once the layers of material have taken shape, post-processing is often required. This stage might involve removing any excess powder or material, curing the object under UV light for specific 3D printing processes, or applying finishing touches to enhance the aesthetics and functionality of the printed thing.

Ready to transform your digital models into physical reality with 3D Musketeers? Reach out to us, and let’s start materializing your ideas!

Keep Up with the 3D Printing Industry with 3D Musketeers

As you immerse yourself deeper into the fascinating realm of 3D printing, remember the possibilities are virtually endless. Stay updated with the latest trends and advancements in the 3D printing industry by connecting with us on our Facebook, Twitter, and LinkedIn. Also, remember to subscribe to our YouTube Channel for informative and engaging content. Let’s make the future together!

Recent Comments