3D printing technology provides such a wide range of applications for trial lawyers that any law firm would be remiss to ignore the benefits that 3D printed objects bring to the civil litigation process, pre-trial investigation, and courtroom demonstrations!

6 Lawyers Who Use 3D Printing Technology

Personal Injury Lawyer

Personal injury lawyers represent claimants who suffer from a physical, psychological, or emotional injury caused by negligence from an individual, business, or organization.

The most common personal injury claims include:

- car accidents

- medical malpractice

- assault

- product liability

- wrongful death

- workplace accidents

- premises liability personal injury

A personal injury lawyer needs to investigate claims, gather evidence, document injuries, and expenses, review medical documents, and of course, represent their clients during trial.

But even with concrete evidence, if the jury struggles to conceptualize spatial relationships or series of events of the incident, then the lawyer’s argument is in jeopardy.

“The success of your presentation will be judged not by the knowledge you send but by what the listener receives.”

– Lilly Walters

Courtroom graphics are best for charts and diagrams and 3D animations can be simplistic and clunky.

Personal injury trial presentations benefit from presenting 3D printed models of:

- Motor Vehicles

- Crash Scene Reconstruction

- Mock Crash Scenes

- Crash Scene Evidence

- Crime Scenes

- Crime Scene Evidence

- Anatomical Models of Injury

- Assault Weapon Markings

- Architectural Models

Medical Malpractice Lawyer

A medical malpractice attorney represents those suffering from medical negligence, misdiagnosis, improper treatment, or botched surgery in a medical malpractice claim. Or they represent the defendants, such as a medical expert, health care professional, or health care provider, in medical malpractice lawsuits.

Medical jargon is advanced for those not involved in the practice of medicine or medical services.

If medical professionals struggle to provide their expert opinion testimony in layman’s terms, then the jury panel may develop a convoluted understanding of the facts.

Plus we all know how easily medical misinformation spreads.

Medical malpractice lawyers must ensure that the jury panel understands the facts of the case.

This can be achieved with 3D printed models to represent:

- Computerized Tomography (CT) Patient Scans

- Magnetic Resonance Imaging (MRI) Patient Scans

- Multiple CT or MRI Patient Scans representing Medical Malpractice or Clinical Negligence Timeline

- Mechanism of Injury (MOI)

- Medical Device Replicas

- Anatomical Relationships

Workers Compensation Lawyer

Workers compensation lawyers protect workers from wrongful employer retaliation and unfairly denied claims.

They also represent injured workers seeking punitive damages to cover medical expenses and emotional distress from permanent disability caused by a workplace incident or negligence.

Workers compensation lawyers may also represent family members seeking compensation payments for a worker’s wrongful death.

The most common examples of workers compensation claims involve:

- Overexertion

- Slips and falls

- Struck by an Object

- Machinery Accidents

- Falling

- Workplace Violence

3D printed architectural models and landscapes of the actual workplace provide context and understanding to the workers compensation trial.

2D photographs lack full context

Just look at a safety photo on social media and read all the comments from arguing safety professionals. If subject matter experts can’t even agree on snapshots, forget about members of the general public understanding workplace hazards or incident evidence.

Context is key!

3D scans of industrial workplaces can be uploaded into CAD software and 3D printed at scale for jurors to view and fully understand hazards, spatial relationships, and safety elements (or the lack thereof in the case of willful negligence).

Toxic Tort Lawyer

These lawyers handle toxic tort litigations that involve injury from poisonous or hazardous materials.

Toxic tort claims might concern prescription drugs, pesticides, asbestos exposure, lead-based paint, hazardous waste, among others. Toxic tort claims could be entirely personal injury cases or cross-over into workers’ compensation. Toxic tort litigators might represent the affected individuals, employers, or corporations.

Toxic tort attorneys similarly benefit from 3D prints of:

- Bodily Injuries

- Replicas of Industrial Products

- Property Damage

- Architectural Model of the Chemical Plant

Military Lawyer

Military attorneys, or rather the Judge Advocate General’s Corps (a.k.a. JAG or JAG Corps), provide military members legal counsel and representation in civil or criminal cases under the jurisdiction of the Uniform Code of Military Justice (UCMJ).

Active duty military members facing disciplinary matters, dishonorable discharge, or court-martial proceedings may go to trial by jury members equal in rank or higher than the accused military member.

If jurors are not as well versed in applicable technical or medical jargon, then their lack of demonstrative evidence jeopardizes the case.

Hence, even a military law attorney benefits from leveraging 3D printing technology to support compelling arguments in any legal matter.

3D Prints Help Law Enforcement Professionals Too

Law enforcement agencies and police departments should take full advantage of 3D printing as a tool of investigation. Lawyers, pay attention. This could affect you during your presentation of evidence.

Crime Scene Reconstructionist

Imagine assembling a jigsaw puzzle… better yet, imagine constructing a challenging adult LEGO® set without being able to reference the box top. Oh, and some pieces are missing!

These are challenges faced by crime scene reconstructionists. These forensics experts must use what evidence is available to them to figure out exactly what happened.

There are 5 classifications of reconstruction types:

- Specific Type of Incident Reconstruction

- Specific Events Reconstruction

- Degree of Involvement Reconstruction

- Specific Type of Physical Evidence Reconstruction

- Special Areas or Determinations in Reconstruction

In any of these classifications, several types of evidence patterns are used for reconstruction analysis, such as:

- Bloodstain and Blood Splatter Patterns

- Glass Fracture and Distribution Patterns

- Fire Burn Patterns

- Furniture Position Patterns

- Track-Trail Patterns

- Tire and Skid Mark Patterns

- Clothing or Article Patterns

- Modus Operandi and Scene Profile Patterns

- Weapon-Specific Markings on Projectiles

- Post-Muzzle Markings and Trace Evidence

- Shell Casing Ejection Patterns

- Vehicle Dynamics in Accident Reconstruction

One of the best methods for preserving the physical evidence for crime scene reconstruction is… no, not just photographs. 3D scans!

3D scanning is a noninvasive and nondestructive method of preserving the entire crime scene with a high level of accuracy. Any crime scene can be replicated with exactness before evidence collection, thanks to 3D scanning technology.

3D scanners are especially valuable in the collection and preservation of fragile or transient evidence such as:

- Teeth Marks

- Skeletal Remains

- Fire Accelerants

- Shoe and Tire Impressions

- Gunshot Residue and Patterns

- Barfoot Impressions in the Ground or on Blood

3D scans can become 3D-printed objects which demonstrate miniature architectural scale models, actual-size scale models of evidence, or enlarged models to demonstrate finer details. All of which can assist crime scene reconstructionists to piece the puzzle together.

3D print models help crime scene reconstructionists solve crimes and serve as demonstrative evidence.

Trace Evidence Examiners

Have you ever broken a vase and tried to put it back together with superglue? Did you try to match each delicate ceramic piece to the correct fracture line? That is what a trace evidence examiner does during physical fit analysis!

A physical fit analysis (PFA) involves finding matches between fragments of trace evidence.

‘Trace evidence’ is remnants from objects that have come into contact with each other such as fibers, flakes of paint, bits of glass, or bone fragments. Trace evidence examiners analyze those pieces to determine the origin of the object and form connections between scenes, place suspects at the crime scene and reconstruct the crime.

“A positive physical fit indicates that two or more fragments have originated from the same object. Confirming physical fit at a crime scene is essential to draw links between locations, place suspects at the scene, and allow for object reconstruction.”

– Dr. Katherine Brown, Senior Lecturer, Institute of Criminal Justice Studies, University of Portsmouth

Physical fit analysis, fracture match analysis, and tool mark-related examinations require manual handling of trace evidence which is particularly fragile. Some even pose a biological or mechanical hazard to examiners.

3D printing technology reduces the risk of damage and contamination by limiting the manual handling of fragile trace evidence, which preserves the integrity of the evidence.

Researchers at the University of Portsmouth Institute of Criminal Justice Studies found that fused filament deposition (FFD) 3D printing is accurate and creates sufficiently detailed physical replicas of bone fragments to perform physical fit analysis PFA, and bone fragment reconstruction.

3D printing offers trace evidence examiners a reliable method for safely handling hazardous evidence, enlarging microscale evidence up for ease of handling and presentation, even minimizing larger and heavier evidence down to more manageable models for ease of transportation.

3D printed replicas of trace evidence also open up the possibility of demonstrating physical fit and fragment matches in court.

Facial Reconstruction Sculptors

Facial reconstruction is a subfield of archeology and forensic anthropology that combines science and artistic skill with the goal of identifying people of the past or suspected victims to bring closure to grieving loved ones and to solve criminal investigations.

The victim’s family, friends, or acquaintances are required to visually identify the victim’s face, but sometimes the face is unrecognizable due to decomposition, destruction, or blunt force damage.

When conventional methods of positively identifying a person (dental records, radiography, DNA analysis) are infeasible then forensic teams rely on a forensic artist.

Traditionally, facial reconstructionist sculptors use facial approximation to add clay, plastic, or wax directly to the victim’s skull to replicate facial tissue thickness, muscles of mastication, lips, subcutaneous fat, skin, and facial expression. There are a few drawbacks to this method:

- Bone is porous and fragile.

- Manual handling of human remains in some cultures is unethical.

- Facial tissue depth varies for different sexes, ethnic groups, ages, and regions of the face.

- Using the average thickness of the soft tissues may not sufficiently represent the victim to the point of positive identification.

- To create variations of the tissue depth, hair, nose, or ears the sculptor would have to make modification after modification, which could inherently damage the skull.

- Even to make castings of the skull with gypsum, the original skull can still be damaged due to excessive handling.

Luckily 3D printing technology provides the optimal solution for creating detailed replicas of the human skull.

Although traditional gypsum skull replicas have better surface quality in comparison, the level of detail that 3D printers can bring to key features of skull replicas (e.g. eye cavities and denture geometry) far exceeds that which can be produced by a gypsum skull replica.

The benefits of utilizing 3D printing technology for facial reconstruction are clear:

- There is less manual handling of fragile evidence.

- Less potential for damaging such evidence.

- Preservation of evidence.

- 3D printing requires little supervision once started.

3D printed human skulls in combination with the Manchester method provide facial reconstruction sculptors with an easily reproducible, highly-detailed, and cost-effective method for creating several variations of a facial reconstruction that increases the likelihood of positive identification of the victim.

Defense POW/MIA Accounting Agency (DPAA)

It is the critical mission of the United States Defense POW/MIA Accounting Agency (DPAA) to find and identify service members who were Prisoners of War (POW) or Missing In Action (MIA) from all wars and conflicts.

Forensic scientists at the Central Identification Lab of the DPAA combine traditional methods of positive identification with modern 3D printing technology.

In-between identifying fallen service members, this team actively works toward refining their process through practice with 3D printed skulls from CT scans of living humans.

3D print models of skulls produced by a ZPrinter, a multicolor printer with unparalleled accuracy, have no statistically significant difference between measurements of the original skull and its ZPrinted model.

Skulls reveal sex and race, but digital images of unidentified remains superimposed onto 3D prints of skulls compared to photographs of known service members will reveal much more.

Thanks to this technique, fallen service members can be identified, give families closure, and finally lay their remains to rest.

Trier of Fact: Arbiter, Judges, and Jurors

Of all who need 3D printing technology in law and justice, one who benefits the most is the trier of fact: arbiters, judges, and jury members.

Evidence presented to arbiters, judges, and trial jurors must be admissible: relevant, reliable, and without bias.

Actual evidence, especially trace or transient, can be problematic due to:

- risk of biohealth hazards

- fragility

- the morality of handling human remains

- possibility of inflicting emotional distress

Even documentary evidence of sexual assault, child abuse, decomposing bodies, human remains, etc. could evoke bias.

3D printed demonstrative evidence increases admissibility by reducing the gruesomeness of the demonstrative exhibits, eliminating jury bias while sharing pertinent information, conveying an accurate depiction, and upholding the required standards for a fair trial.

3D printed evidence does not require nitrile gloves to handle and does not risk contact with bloodborne pathogens or other biological hazards.

When judges and jurors can view demonstrative evidence as a 3D-printed object during courtroom demonstrations, it increases their understanding of:

- Complex anatomical relationships;

- Radiographic data;

- Medical or technical jargon;

- Science-intensive language;

- Spatial relationships; and

- The sequence of events.

This experience also creates a strong impression and maximizes retention of information to the memory through active trial engagement.

“There is a special need for techniques that allow pathologies to be presented clearly in the courtroom. For medical laymen such as judges, lawyers, and especially relatives of murder victims, the presentation of autopsy photographs can be disturbing, making findings difficult to present this way. From a juror’s perspective, being able to see such an object which is much more familiar than trying to interpret radiographs allows for a better spatial appreciation and understanding of injuries. Unlike volume renderings, 3D printed models offer real three-dimensionality as well as a haptic component, which make it easier for medical laymen to understand.”

– Eugene Liscio, President of the International Association of Forensic & Security Metrology (IAFSM)

Admissibility, safety, and fairness are critical factors in presenting evidence to arbiters, judges, and trial jurors.

3D printed demonstrative evidence:

- eliminates bias

- protects fragile, actual evidence

- eliminates biological hazards

- mitigates emotional distress

- encourages neutrality

- increases memory retention

- increases engagement

- increases comprehension

Now you might be wondering, how do I turn my real evidence into 3D prints?

Read about the 3D scan to 3D print process in the next section!

Or schedule a free consultation with 3D Musketeers since you have so much you already have to read!

3D Scan to 3D Print Process

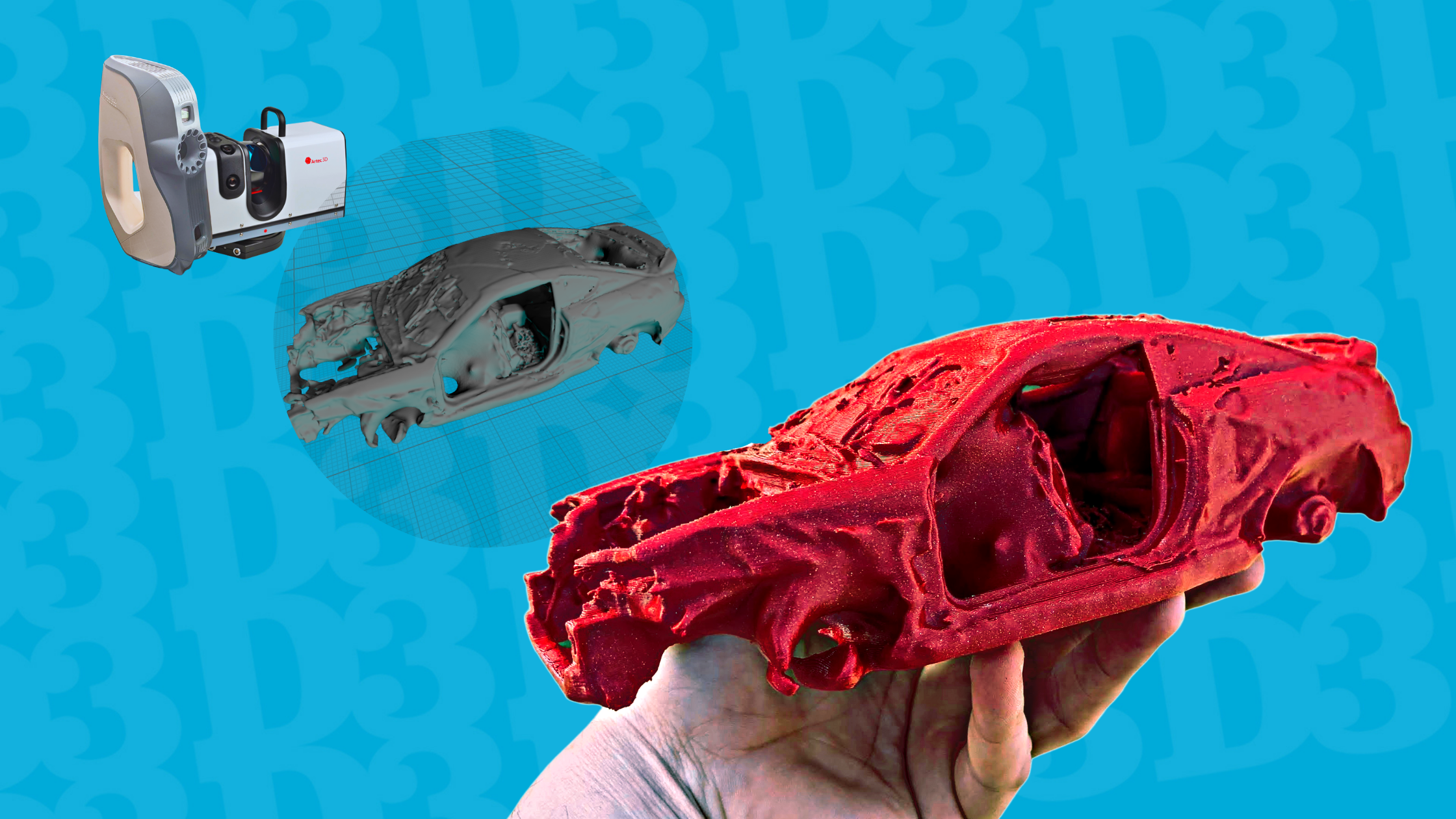

Law enforcement professionals rely on 3D scanners and 3D printing technology for accurate analysis of vehicle dynamics, car crash reconstruction, and anatomical models with accurate surface finishes.

Scanning Vehicle Collisions

Whether documenting severe accident scenes or controlled crash scenes from a car safety testing lab, there are 3 main techniques for capturing crumpled vehicles for the 3D Scan-to-Print process:

- 3D Laser scanners

- Structured-light scanners

- Photogrammetry

3D Laser Scanners

Laser scanners emit a rapidly pulsing or continuous laser beam while rotating 360° from a tripod and sweeping the area.

When the beam reflects from the accident vehicle, the scanner calculates and records each distance measurement scan, which results in 3D coordinates that create a detailed 3D point cloud model.

At 3D Musketeers, we utilize the Artec Ray 3D Laser Scanner for submillimeter accuracy at long distance ranges.

Our laser scanner can scan the entirety of the Raymond James Stadium or the Statue of Liberty in one scan from a football field distance away with accuracy within the thickness of a credit card!

In reality, we would capture at least 6-scans of the accident vehicle exterior from a distance of 5-15 meters.

This process takes about 3 hours

Structured-Light 3D Scanners

Structured-light scanners project 3 to 10 patterns of light onto the accident vehicle. As the light patterns deform around the accident vehicle, the scanner aligns those curvatures in software to create a 3D model.

At 3D Musketeers, we use the Artec Eva: a short-range structured-light 3D scanner for scanning the finite details of the accident vehicle, such as the interior.

It takes approximately 5 to 6 hours to capture the details of the incident.

Details are vital! They create depth and build the bigger picture. We utilize the Artec Ray and the Artec Eva to form the most in-depth 3D model.

With both scanners, the typical crash scene scanning process takes about 6-8 hours.

Photogrammetry

Unlike structured-light and laser scanning techniques, photogrammetry requires hundreds if not thousands of individual photos taken from a DSLR camera.

Photogrammetry is a method that requires a photographer to manually capture still images from all angles and at varying heights around the object that then get uploaded into the software. The software compiles hundreds to thousands of photos into a 3D model.

Although this method can produce highly-detailed 3D models, it can take significantly longer to capture enough workable digital files compared to the scanning methods.

It is less practical to use photogrammetry on vehicle collisions, but a good method for scanning the exterior of a human body, or of a toy action figurine.

Scanning Bodies – Dead Or Alive!

Whether scanning an injured person or a victim from the morgue, specific medical scanning methods work best for the 3D Scan-to-Print process:

MRIs and CT scans.

CT scanners use X-ray beams that rotate around a supine body. A computer processor then combines the X-rays to produce high-resolution, cross-sectional images. Image slices are 2D pictures stacked together to form a 3D model. CT scans are more detailed than conventional X-rays and are the preferred 3D scan method for 3D printing.

A CT scan typically takes 5 minutes to complete.

MRIs use a magnetic field and radiofrequency pulses to capture images of protons that release electromagnetic energy. Based on how quickly energy is released, MRIs differentiate between different types of body tissues.

An MRI scan typically takes 30 minutes to complete.

CT scans are great for revealing bone detail, soft tissue, and organs, whereas MRIs are best for soft tissue. Hospitals or outpatient facilities, of course, are equipped for medical scans, but keep in mind that flawed data create flawed prints.

At 3D Musketeers, we are happy to provide consultation services to guide you on the ideal scanner parameters to produce the best quality data for 3D printed anatomical models.

3D Modeling Process

Once CAD software composites a 3D model from the scanner digital files, our job is to prepare the 3D model for the printer! This process includes removing layers to reveal what is required, such as fat, organs, or skin.

3D modeling is a moderately time-consuming process. The turnaround ranges from a few hours to a couple of days; it depends on the complexity of the 3D model.

See the 3D modeling process in action on our live stream PRINT MY SPINE! Let’s 3D print Medical Models!

3D Print Process

The final stages of the Scan-to-Print process are:

- 3D Slicing

- 3D Printing

- 3D Object Clean-Up

3D Slicer

There are various printer settings available when printing a 3D object.

The 3D slicing step is the process in which the user decides what 3D print parameters to use such as:

- temperature

- platform adhesion

- layer height

- shell thickness

- infill pattern

- fill density

The 3D slicer software processes the information and sends the instructions (G-code) to the 3D printer.

The 3D slicer process takes up to 10 minutes.

3D Printing & 3D Object Clean-Up

The 3D printing process usually requires multiple days to complete depending upon the scale and complexity of the 3D print files.

Support material is removed while maintaining the details. We avoid sanding 3D prints to preserve the detailed models as much as possible. The cleaner the digital model to begin with, the better the 3D print.

Contact 3D Musketeers for a complete 3D scan to 3D print service for models to assist with:

- Vehicle Speed Analysis

- Vehicle Damage Analysis

- Accident Reconstruction

- Crime Scene Models

- Anatomical Models

- Demonstrative Evidence

Not convinced whether you should use 3D prints during your presentation of evidence? Read on!

Should 3D Printed Demonstrative Evidence Be Used During Courtroom Presentations?

Types of Evidence

The major four types of evidence are:

- Real Evidence

- Demonstrative Evidence

- Documentary Evidence

- Testimonial Evidence

3D print models fall under the category of demonstrative, though they can represent either a true-to-life model of real evidence or a representation of documentary evidence (such as a medical scan).

What Is Admissible Evidence

Admissible evidence must provide relevant information in proving or disproving an element of the case. Irrelevant evidence is not admissible and cannot be used as evidence at trial.

Not all relevant evidence is admissible either. Evidence obtained in violation of the defendant’s constitutional rights, such as without a search warrant, is not admissible. The judge could decide to exclude admissible evidence from courtroom use if it could mislead, confuse, or bias jurors.

Proof Beyond A Reasonable… Doubt?

There cannot be an ounce of doubt to convict a guilty criminal! That is the burden of proving a defendant guilty beyond a reasonable doubt.

You’d be lucky to have a cardiac surgeon, biomedical engineer, or CAD draftsperson serving the jury panel. More likely than not, your jury will have a basic understanding of anatomy and average spatial-visualization intelligence at best.

The jury can’t be confused when listening to expert testimony or presentation of evidence! 3D printing technology clears any confusion and alleviates the burden of proof beyond a reasonable doubt.

3D printed models are excellent for demonstrative purposes. They can:

- demonstrate anatomical relationships

- demonstrate spatial relationships

- demonstrate the sequences of events

- help jurors understand facts of medical malpractice or violent crime cases

- provide clarification

- eliminate subconscious bias

How 3D Prints Can Eliminate Bias

Gruesome evidence could create subconscious bias and case triers of fact to perceive the defendant unfavorably. Evidence that could create bias risks the fairness of the jury trial and becomes inadmissible. One tactic for eliminating jury bias is to present demonstrative evidence as a 3D-printed object.

Antemortem and postmortem anatomical exhibits and visual evidence, especially in crimes involving violent crimes against children, can unfairly bias the jury against the defendant.

Imagine a court case involving a defendant who attacked a child by driving a screwdriver through a child victim’s eye socket. A criminal trial such as that would surely cause the jury to look unfavorably upon the defendant. The jury would be less likely to look at relevant evidence objectively.

That’s bad news if the wrong suspect is on trial.

Full-color violent visual evidence elicits a strong emotional impact on the jury and compromises the fairness of the trial. Single-color 3D printed models to lessen the graphicness of those medical scans while facilitating a well-informed jury verdict without creating bias.

Remember:

- 3D prints that are too realistic could create bias.

- 3D prints that are too abstract might violate the requirement for the evidence to be accurate.

3D scanning technology in conjunction with 3D printing technology is the optimal method for striking that perfect balance between accuracy and neutrality.

Closing Argument To Summarize It All!

It’s evident that 3D printing technology provides considerable benefits for lawyers during courtroom presentations and deliberations.

Who Really Uses 3D Printed Models?

- Personal injury, medical malpractice, workers’ compensation, toxic tort, criminal and military lawyers,

- Insurance companies,

- Crime scene reconstructionists,

- Trace evidence examiners,

- Facial reconstruction sculptors,

- Judges and jurors, and

- Arbiters and mediators.

When To Use 3D Printed Models

- Crime scene analysis,

- Forensics analysis to preserve fragile evidence,

- Facial reconstruction for positive identification,

- Pre-litigation investigation, and

- To replicate demonstrative evidence during mediation, arbitration, or litigation.

What 3D Printed Models Can Represent

- Miniature, 1:1 scale, or enlarged scale models;

- Reconstruction of violent home invasions, vehicular incidents, workplace incidents or crime scenes, crime scene sequence of events;

- Replica of the skull for forensic facial reconstruction;

- Anatomical relationships;

- Impact from blunt trauma;

- Weapon/ bullet entry and exit holes;

- Causes and characteristics of injury; and more!

3D Scan to 3D Print Process

Times listed are estimates and vary due to many factors.

- Scan

- ~ 5 minutes: CT Scan

- ~ 30 minutes: MRI Scan

- ~ 6-8 hours: Laser and Structured-Light Scanners

- ~ Hours-Days: Photogrammetry

- Model (couple hours or couple days)

- Print (typical 5-7 days)

Advantages of 3D Printed Models

- Preserve transient and fragile evidence,

- Preserve human remains,

- Allow for manual handling of skull model without damaging the original,

- Improve the efficiency of the facial reconstruction process,

- Add clarity to expert testimony,

- Improve understanding of technical or medical evidence,

- Reduce confusion and risk of cognitive bias,

- Improve retention of information, and

- Provide the best means for an objective, well-informed jury verdict.

It is truly astonishing what potential 3D printing technology brings to law and justice!

Leave us a comment if you found this insightful! As always, we encourage you to MAKE AWESOME… courtroom presentations!

Blog adjourned.