Creating a prototype in the traditional way is costly and time-consuming. Manufacturing errors and expensive materials can make a prototype cost just as much as the final product.

Rapid prototyping is a solution to this common problem. Imagine being able to cut down on costs while your product is in development and saving hours of work that comes with making multiple prototypes before perfecting the final one.

Learn how rapid prototyping can save your business both time and money.

What is Rapid Prototyping?

It’s the process of creating a prototype rapidly. This way designers can show their new ideas to others and receive feedback without too much investment in the materials and equipment that is required to create a prototype.

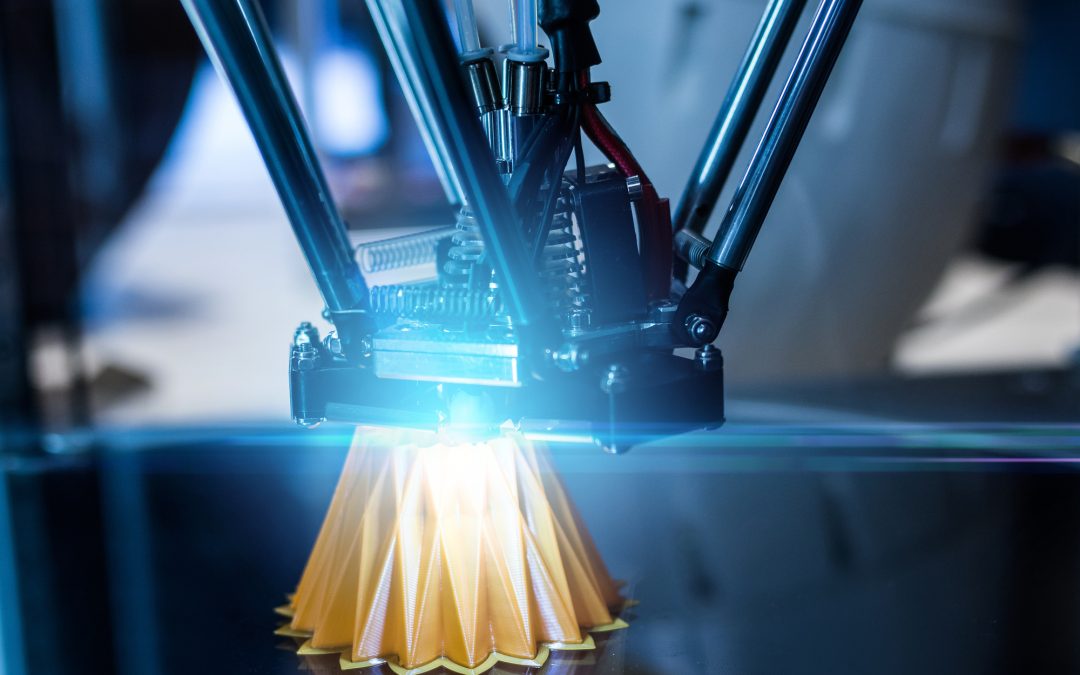

It utilizes a variety of different techniques including fused filament fabrication and additive manufacturing. You don’t need any tooling to create a rapid prototype and it’s very free in form.

In manufacturing, prototypes are categorized by their accuracy, also known as their fidelity. The accuracy needed for the prototype is determined by how far along in the process the design is.

The closer to completion, the more accurate it needs to be. There are a few standard fidelity types you should familiarize yourself with.

Fidelity Types

A low-fidelity prototype is as simple as possible and is fast to make. It requires minimal resources because it’s early in the creation process.

High-fidelity prototypes work in a similar way as the final product. They take longer to make and use more expensive materials.

How 3D Printing can Help your Business

3D printing is not the same as a rapid prototype. 3D printing is the process used to make a rapid prototype. It’s also commonly used in tandem with other processes such as fused deposition modeling (FDM), resin printing, and Stereolithography (SLA) 3D printing.

There are many benefits to 3D printing. It can help grow your business and save you money. The versatility and fast turn-around times are also great reasons to use a 3D printing service.

Advantages of 3D Printing

One advantage of 3D printing is that you save time and money by not having to set up tools and workstations to make your prototype.

3D printing also provides you with the opportunity to test your product, and you can refine your idea and minimize any flaws without having to make multiple costly prototypes.

Taking an idea from your mind, putting it into a blueprint, then into a product is hard to do. Most people can’t visualize a concept until they see it in 3D space. For example, if you’re seeking investors for an idea, making a low-fidelity prototype will help the investors understand the idea. Then, by the time you get to the final design stages, an investor can feel confident in investing money into your product. It’s often much easier to get investors for an already tested prototype than having nothing to show at all.

Hire a 3D Printing Service Today

With rapid prototyping, your business can quickly present innovative ideas. The visualization of the product will help accentuate problems before they become too expensive to modify after the final design.

By creating rough versions of your product, you reduce so much risk. Sometimes good ideas don’t work and it’s better to know your idea’s a fluke before investing time and money into making a final product that will fail.

Contact us for a free consultation with one of our experts.